|

| Extended Reach Drilling |

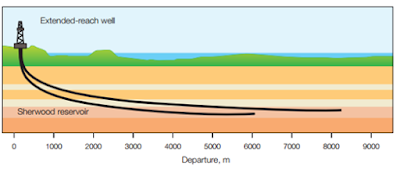

An extended-reach well is one in which the ratio of the measured depth (MD) vs. the true vertical depth (TVD) is at least 2:1.

Extended-reach wells are expensive and technically challenging, however, they can add value to drilling operations by making it possible to reduce costly subsea equipment and pipelines, by using satellite field development, by developing near-shore fields from onshore, and by reducing the environmental impact by developing fields from pads.

Extended Reach Drilling allows producers to reach deposits that are great distances away from the drilling rig and this help producers tap oil and natural gas deposits under surface areas where a vertical well cannot be drilled, such as under developed or environmentally sensitive areas.

Today, as the Horizontal Drilling, also the Extend Reach Drilling use the technology of the “RSS: Rotary Steerable System” that permit to steer an hole continuing the rotation of the drilling string with an improvement of the safety and the drilling efficiency.

Moreover, the selection of a drilling fluid must balance a number of critical factors.

The fluid must provide

- a stable wellbore for drilling long open- hole intervals at high angles, maximize lubricity to reduce torque and drag, develop proper rheology for effective cuttings transport, minimize the potential for problems such as differential sticking and lost circulation, minimize formation damage of productive intervals.

Pipe rotation is another critical factor in hole cleaning.

The objective of the hole- cleaning program in ERW is to improve drilling performance by avoiding stuck pipe, avoiding tight hole on connections and trips, maximizing the footage drilled between wiper trips, eliminating backreaming trips prior to reaching the casing point and maximizing daily drilling progress.

No comments:

Post a Comment