|

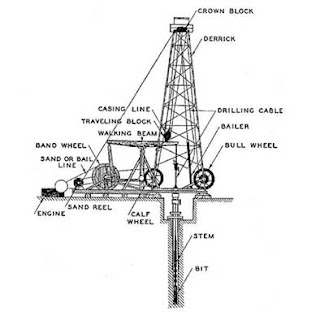

| Cable Tool Drilling Bit |

Cable tool method has its beginnings 4000 years ago in China. it was the earliest drilling method and has been in continuous use for about 4000 years. The Chinese used tools constructed of bamboo and well depths of 3000 ft are recorded. However, wells of these depth often took generations to complete.

Cable tool rigs are sometimes called pounders, percussion, spudder or walking beam rigs. They operate repeatedly lifting and dropping a heavy string of drilling tools into the boreholes. The drill bits breaks or crushes consolidate rock into small fragments. When drilling in unconsolidated formations, the bit primarily loosens material.

Water, either from the formation or added by the driller, mixes the crushed or loosened into a slurry at the bottom of the borehole. An experienced cable tool driller feels when the accumulated slurry has reached the point where it is reducing bi penetration to an unacceptably slow level. At this point the slurry is removed from the borehole by a bailer. Once the slurry is removed, the bit is reinserted into the hole and drilling continues.

|

| Cable Tool Drilling Rig |

Often a cable-tool rig drills only one-tenth as fast as a rotary rig in comparable formations. However, the cost of a cable-tool rig is substantially less than a rotary rig. This tends to compensate for its slower drilling rate. A distinct disadvantage of the cable-tool method is that when high-pressure oil and gas formations are encountered, there is no fluid in the hole to control them. The result is frequent blowouts.

When a blowout occurs, the oil and gas from the subsurface formation rush to the surface and flow uncontrolled. A blowout may spray the oil and gas several hundred feet into the air, and there is always great danger of a fire. Because of its slow penetration rate and the hazard of blowouts, the cable-tool method is seldom used on wells deeper than (3000 ft or 900 meters). Even on shallower wells, this method has largely been replaced by the rotary method.

Woah! Those are really some lesser-known facts about the evolution of PDC drill bits as we know them today! Rockpecker is the best in the business today.

ReplyDeletePDC Drill Bits